Achieving True 5S: Overcoming Barriers to Standardisation and Sustainability

Understanding 5S and Its Importance

5S is more than just a set of steps; it's a philosophy aimed at improving efficiency, safety, and productivity in the workplace. Here's a brief overview of each step:

- Sort: Remove unnecessary items from the workspace.

- Set in Order: Organise the remaining items for easy access.

- Shine: Clean the workspace and maintain its appearance.

- Standardise: Establish standards for maintaining the first three steps.

- Sustain: Ensure continuous adherence to these standards.

The first three steps—Sort, Set in Order, and Shine—are relatively straightforward and often yield immediate, visible improvements. However, without Standardise and Sustain, these improvements are temporary.

The Challenges of Standardising and Sustaining 5S

Many organisations find themselves stuck at the 3S stage. Here are some common obstacles:

- Missing Tools Lead to Delays: Without a robust tracking system, tools can easily go missing, causing delays and inefficiencies as employees search for them.

- Inconsistent Tool Replacements Cause Disorder: When tools are replaced without adhering to standards, it leads to mismatched and disorganised workspaces.

- Lack of Documented Processes: Without clear, documented procedures, teams may revert to old habits, undermining the 5S efforts.

These challenges highlight the need for effective standardisation and sustainability practices to achieve lasting results.

Bridging the Gap with KIT - KIT is a transformative system designed to help organisations overcome these challenges and achieve full 5S.

KIT addresses the critical gaps in Standardise and Sustain by:

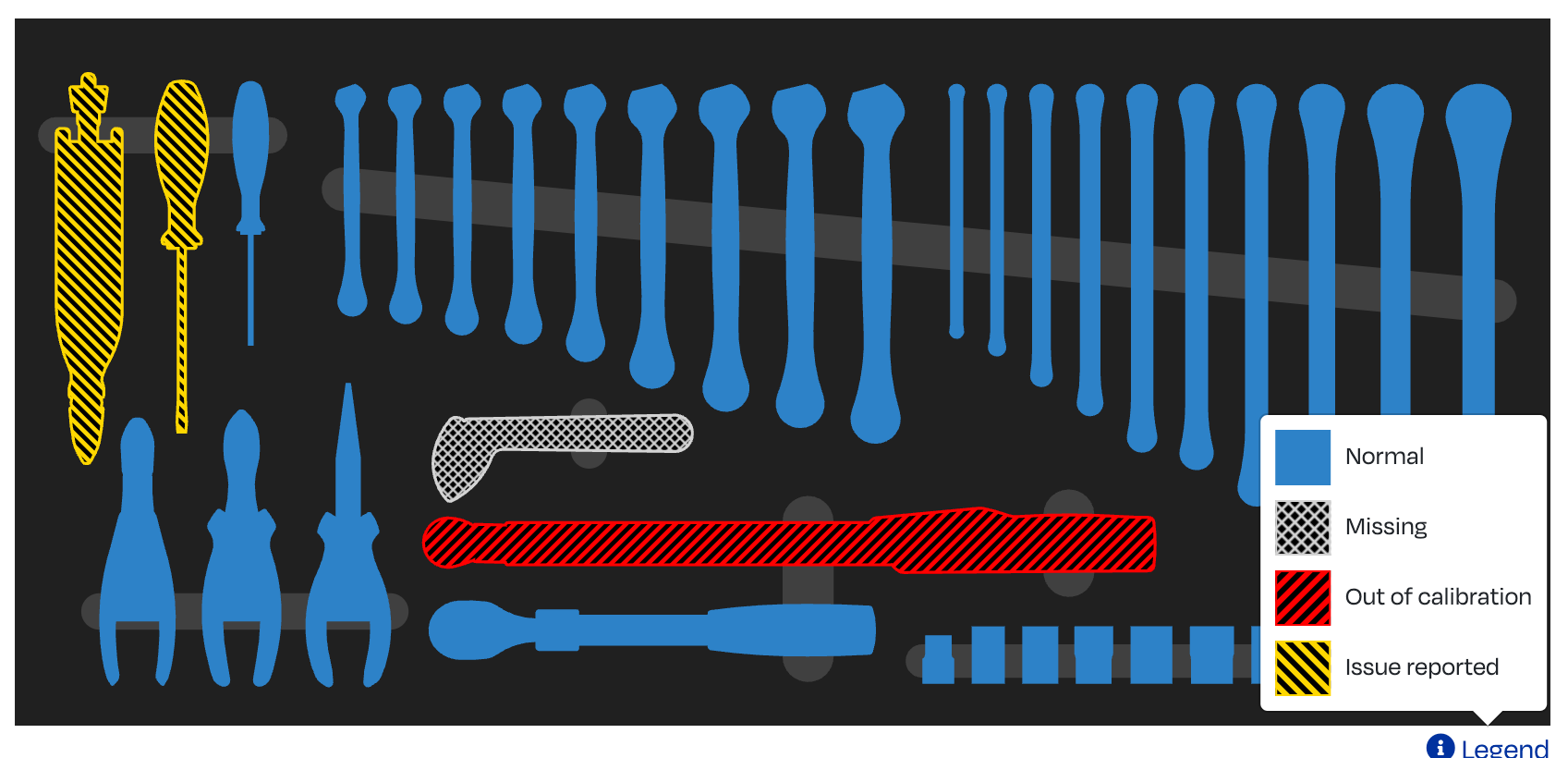

- Efficient Tool Tracking with QR Codes: Each tool is assigned a unique QR code linked to a centralised database. This allows for instant location tracking, accountability across teams, and streamlined audits.

- Centralised Database for Standardisation: KIT's database includes a full inventory of tools, their specifications, and maintenance requirements. It provides clear guidelines for ordering replacements and documents standard operating procedures.

- Automated Processes for Sustainability: KIT offers automatic alerts for reordering tools and performing maintenance, regular reports to highlight trends, and customisable checklists to ensure consistent adherence to 5S principles.

Realising the Full Potential of 5S with KIT

Imagine a workspace where tools are always accounted for, replacements are consistent, and teams have the data they need to improve continuously. KIT makes this vision a reality by addressing the weaknesses in traditional 5S systems. With KIT, organisations can experience:

- Faster workflows with minimal downtime caused by missing tools.

- A culture of accountability, where employees take ownership of their workspace.

- Long-term benefits of 5S, including improved safety, efficiency, and organisation.

Achieve True 5S with KIT

If your organisation has struggled to maintain 5S or has found its efforts stalling at 3S, KIT is the solution you need. With its innovative QR code technology and centralised database, KIT bridges the gap, helping organisations move from short-term fixes to long-term success.

Take the next step toward workplace excellence. Visit thisiskit.com to learn how KIT can help your organisation achieve and sustain true 5S.

)

)

)